Managing the flow of medical and logistical equipment is a complex job… due to the lack of tools. Beds, chairs, monitors, syringe pumps… represent an investment of up to 10% of an establishment’s annual revenue. Each year, maintenance represents 10% of the purchase value… not including the labor dedicated to locating them, as these machines move within and sometimes outside the hospital!

In other words, a family of equipment can lead to 2 to 3 weeks of search, and rarely more than 95% will be found due to uncontrolled exits to other facilities or thefts (which are on the rise). These missing items accumulate and result in a CMMS database with an error rate ranging from 15 to 30%.

In addition to the time lost in searching for equipment, biomedical staff may feel undervalued by these non-value-added tasks. This will result in decreased productivity, increased stress, and a deterioration in the quality of care.

The electricity consumption of devices is the third largest energy expenditure after heating-cooling and lighting. Knowing the activity of devices is essential for understanding their environmental impact. Even better, the CO2 impact of producing a device is irrelevant if it’s not used. Our objective statistical usage data allows for optimization of the fleet: “the best product is the one that doesn’t exist.”

A poorly understood fleet makes purchasing decisions difficult and results in imbalances in investments and uncontrolled needs. Finally, the asset accounting table is largely inaccurate, distorting the institution’s accounting and thus the reality of the necessary investment needs for regulatory authorities.

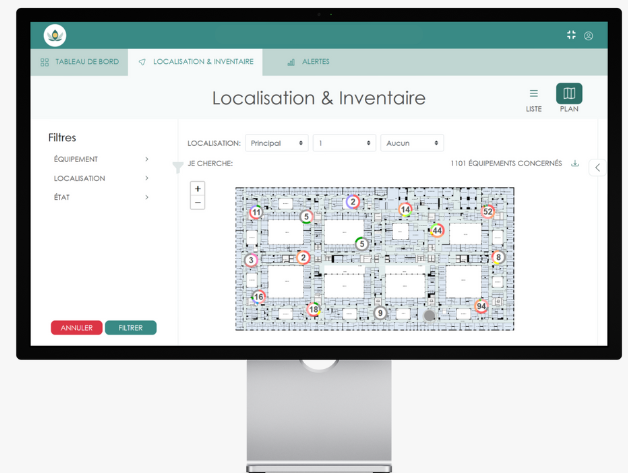

Our users can visualize in real-time the precise location of each equipment, and this in a very repeatable manner and with chosen levels of precision depending on the zones. Superwyze allows you to filter information about your equipment by family, model, location, availability… and then visualize them on a map in real-time, with the certainty of always being on the right floor.

Each user can configure email or SMS alerts for different types of situations, including when equipment leaves the facility, moves from one department to another, reaches the due date for preventive maintenance, or when there is a change in equipment availability. This customization ensures reliable information in critical situations, enabling rapid intervention and optimal resource management.

This feature provides a real-time view of equipment usage or availability. With Superwyze, it’s finally possible to identify available devices and avoid wasting time.

The statistics function provides an in-depth analysis of equipment use over a given period. Users can access detailed reports on the utilization rate and the journey followed by a specific equipment or a family, department by department. These data enable effective planning of preventive maintenance and optimization of investments.

Efficiently monitor your equipment fleet, offering a simplified daily routine for healthcare heroes.

Ensure autonomous temperature traceability throughout the storage and transport of your products.

Optimize healthcare through the geolocation of your patients to improve operational efficiency.

Connected management tools

for hospitals

Follow us

Superwyze continuously invests in R&D to provide the best solutions to meet the needs of healthcare establishments. We would like to thank the Auvergne-Rhône-Alpes Region, for its support in our development by providing financial assistance to advance our projects